Information about Altivar 320 Speed Drive 1.5kW 1-Phase Compact

The Altivar 320 variable speed drive, reference ATV320U15M2C by Schneider Electric, is an advanced solution designed to control synchronous and asynchronous three-phase motors in industrial applications that require precise and efficient control. This drive, optimised for pumping, ventilation, compression, and conveyor applications, is ideal for sectors such as construction, food and beverage, and chemical. With a nominal power of 1.5 kW and a single-phase supply of 200-240 V, the Altivar 320 is compact, efficient, and easy to integrate into modern industrial systems, offering high performance with advanced connectivity and safety features.

Energy saving and improved efficiency:

The Altivar 320 is optimised to offer energy savings of up to 30%, making it an ideal choice for applications where energy efficiency is a priority. This is especially useful in the control of pumps, fans, and compressors, where energy usage can vary significantly. Thanks to its sensorless flux vector control, the drive can accurately manage the torque and speed of the motor, even at low speeds, ensuring optimal performance with minimal energy consumption.

Furthermore, this frequency drive enables the control of synchronous and asynchronous motors, including high-efficiency IE2, IE3, and permanent magnet motors. This ensures that installations comply with energy efficiency regulations, helping to reduce operational costs and environmental impact.

Advanced connectivity and control features:

The Altivar 320 boasts advanced connectivity including Modbus and CANopen as standard communication protocols, facilitating its integration into modern industrial systems. Its RJ45 port allows easy connection to the communication bus, providing direct access to networks such as Ethernet, Profibus DP, DeviceNet, among others, through additional modules. This communication flexibility reduces initial investment and simplifies system design, maintaining the adaptability needed for various applications.

The drive's software also includes advanced safety features that meet industrial machine requirements. These safety features enable safer and more controlled operation, contributing to a more reliable and lower-risk working environment.

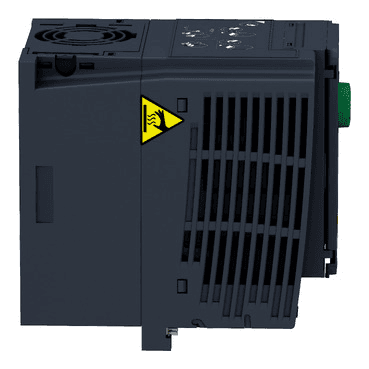

Compact design and easy integration:

The compact form of the Altivar 320 allows for easy installation in environments with limited space. It is designed to be wall-mounted and can be stacked vertically, maximising space utilisation in machine racks. With just IP20 protection, this drive is suitable for controlled environments, such as electrical panels, where the equipment is protected from dust and solid objects.

Installation is made simple thanks to its 4 mounting holes, allowing for quick and secure mounting. The Altivar 320 is prepared to work in a variety of applications, providing consistent and reliable performance, from start to stop, thanks to its precise torque and speed control.

Advanced performance and protection:

This frequency drive is designed to withstand demanding industrial conditions. Its integrated C2 class EMC filter ensures that the device complies with electromagnetic compatibility regulations, ensuring that electromagnetic emissions are kept under control, minimising interference with other equipment.

The Altivar 320 is also equipped with a nominal output current of 8.0 A, ensuring it can handle heavy loads with ease. Its ability to control motors up to 1.5 kW in heavy-duty applications and its 200-240 V power supply allow it to manage a wide range of industrial applications, providing the perfect balance between power and control.

Regulatory compliance and guaranteed safety:

The Altivar 320 complies with various international safety and quality standards, such as CE, UL, CSA, DNV, C-Tick, GOST, CCC, NOM, SEPRO, ensuring it meets the highest standards of reliability and performance. This makes it an ideal choice for projects requiring control devices that guarantee safety and regulatory compliance.

Key technical specifications:

- Motor power: 1.5 kW for heavy-duty loads

- Power supply voltage: 200-240 V (-15% to +10%)

- Nominal output current: 8.0 A

- Communication protocol: Modbus, CANopen

- Network frequency: 50/60 Hz

- Protection degree: IP20

- EMC filters: Integrated C2 class

- Mounting: Wall-mounted, vertical (+/-10°)

Advantages of the Schneider Electric Altivar 320 1.5kW model:

- Energy saving: Up to 30% savings in pumping, ventilation, and compression applications.

- Advanced connectivity: Compatible with Modbus, CANopen, and other industrial networks via optional modules.

- Compact design: Allows mounting in confined spaces, ideal for control panels and racks.

- Precise control: Handling of asynchronous and synchronous motors with sensorless flux vector control.

- Regulatory compliance: International certifications ensuring safety and quality.